A Brief History of Steel Fabrication

Steel and metal fabrication is up there with some of the world’s greatest inventions. The manipulation of metal for human use has been going on for centuries, from our fabrication of armour and jewellery to our modern day uses of steel.

Metal in Prehistory

Ancient civilisation knew of seven metals: iron, tin, copper, gold, lead, mercury and silver. Copper was once the most widely used metal, as it could be heated up and hammered until brittle. Copper soon became too soft for tools that required stiffness, so at some point, somebody added tin to the molten copper and gave birth to bronze, which became the most popular metal for armour and weaponry until people started smelting and welding iron, bringing us into the Iron Age.

How Iron Worked

Iron absorbs carbon at very high temperatures, which lowers the melting point of the metal and results in cast iron. The Chinese had developed blast furnaces in the 6 th century BC, but Europe made them popular during the Middle Ages so they could increase production of cast iron for the purpose of creating tools and weapons. It worked for a while, but the high carbon content in cast iron made the metal brittle.

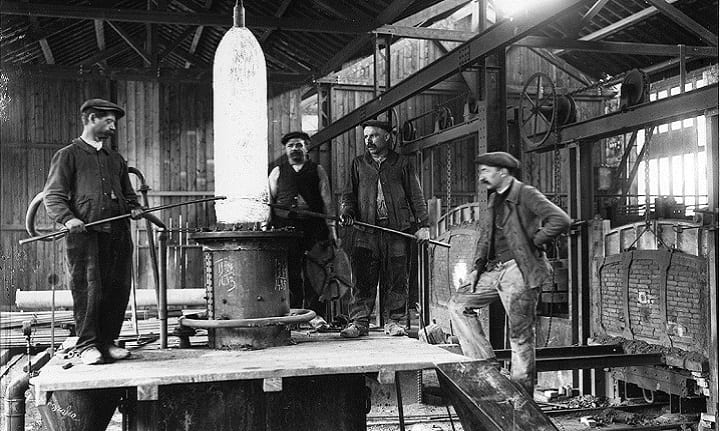

When Iron Became Steel

It wasn’t until the 17th century that Europeans gained a true and advanced knowledge of iron and how the quality of the metal would depend on the ores available. Increasing urbanisation in Europe meant that there was a greater need for structural metal that would be versatile. Railroads were eating up iron, which proved to be too brittle and too inefficient to produce for the modern world.

The breakthrough in the steel industry came in 1856 when Henry Bessemer came up with a way to use oxygen to lower the carbon content in iron, effectively producing what we know of as steel and beginning the modern steel industry.

However, there was a problem with Bessemer’s process. While he was able to remove the carbon, he wasn’t able to remove the oxygen that he introduced into the metal. He was also unable to remove the phosphorus from the metal. So Bessemer added spiegeleisen, a compound of iron, carbon and manganese, to remove the oxygen, an idea he got from British metallurgist Robert Mushet. Then in 1876, a Welshman named Sidney Gilchrist Thomas added limestone

to Bessemer’s process which removed the unwanted phosphorus. All of this teamwork and exchange of ideas led to a booming steel industry. The cost of steel went down and the production went up.

The Rich Get Richer

Capitalists of the 19th century like Andrew Carnegie and Charles Schwab invested in the industry and ended up making millions off it. Carnegie launched his billion dollar industry, US Steel Corporation, in 1901.

To see first-hand how you can benefit from utilising steel fabrication like your ancestors before you, get in touch with Trufab Engineering. We are the best structural steel suppliers and fabricators in Perth.